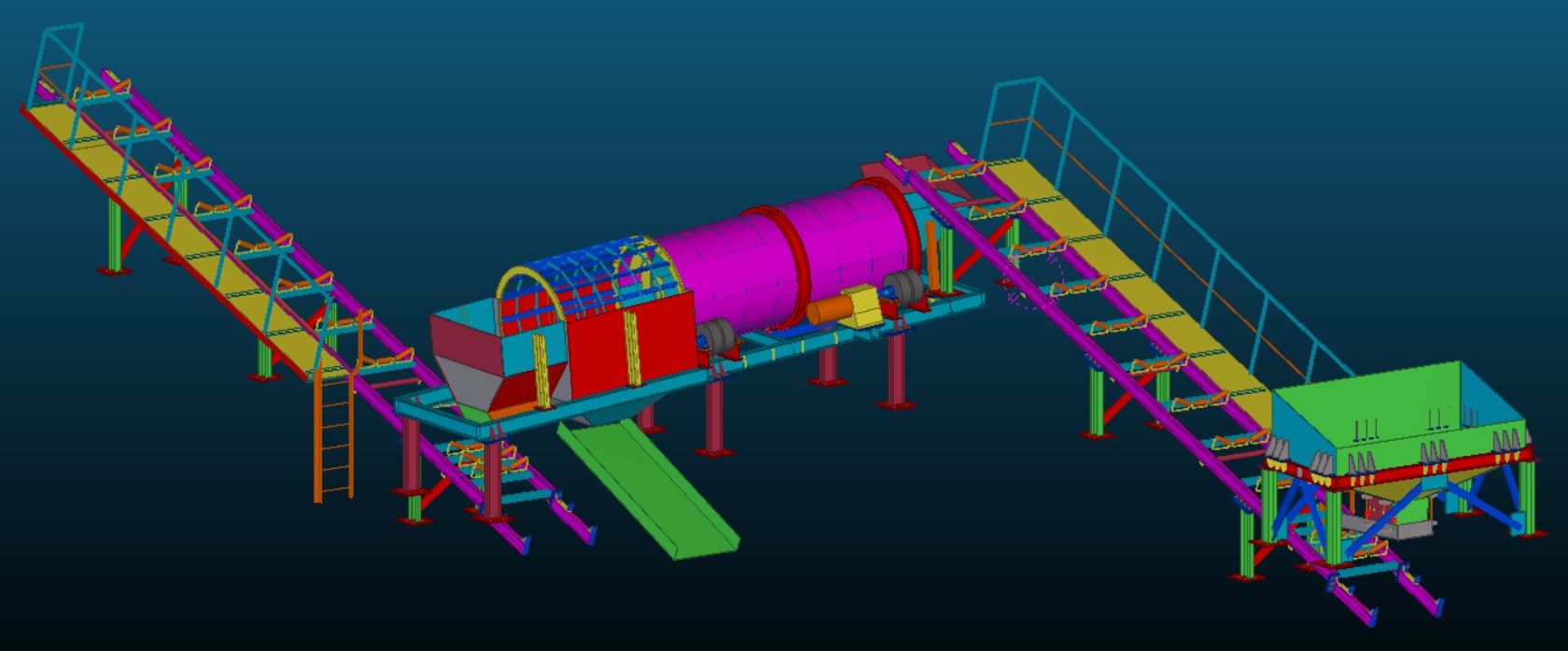

Preparation of a 3D model and Shop Drawing

Preparation of a 3D model of the silo and its supporting structure using Tekla software, examining the connections and seating of the silo on the structure and matching them together, preparing execution drawings including all single parts such as the Development drawing of the silo body and Cone, assembly drawings, and installation drawings for the structure and silo.

1. 3D Model Preparation:

• This involves creating a detailed three-dimensional representation of the silo and its supporting structure. The model includes all necessary dimensions, materials, and components that will be used in the actual construction.

• Tekla allows for precise modeling, which is essential for visualizing how different parts will fit together.

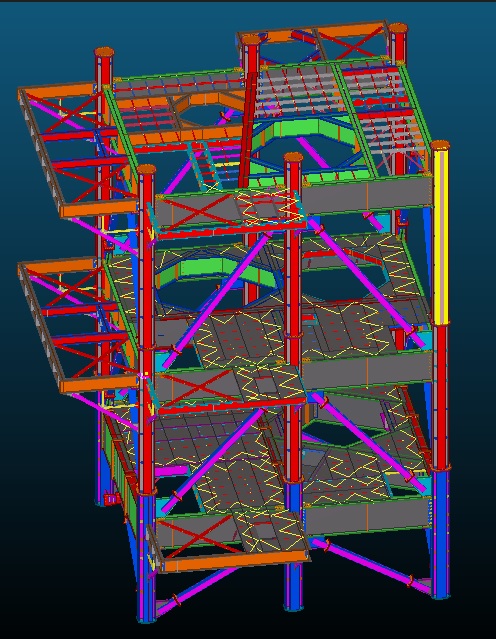

2. Examining Connections and Seating:

• Once the 3D model is created, the next step is to analyze how the silo connects to its supporting structure. This includes looking at the joints, bolts, welds, and other connection types.

• Ensuring that the silo is properly seated on the structure is crucial for stability and safety, as it must withstand various loads and environmental factors.

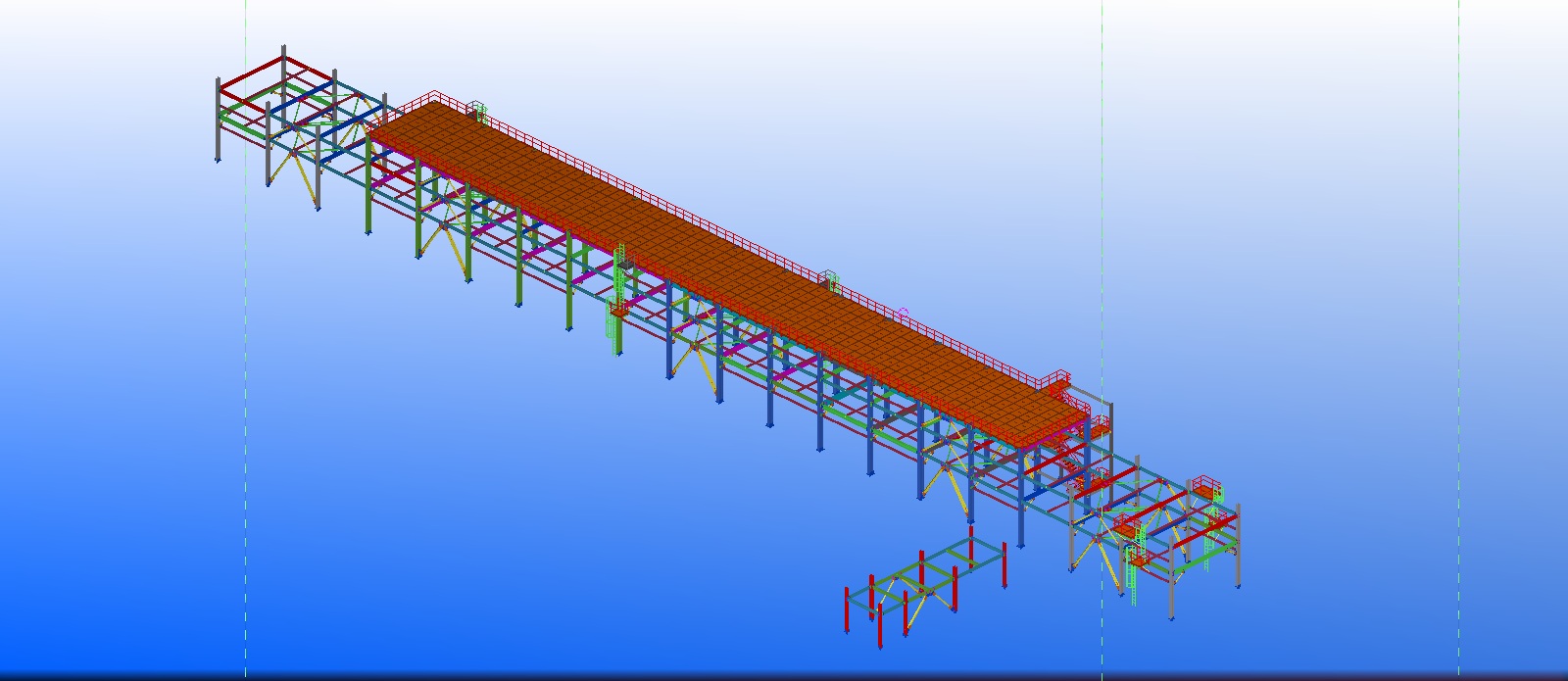

3. Preparing Execution Drawings:

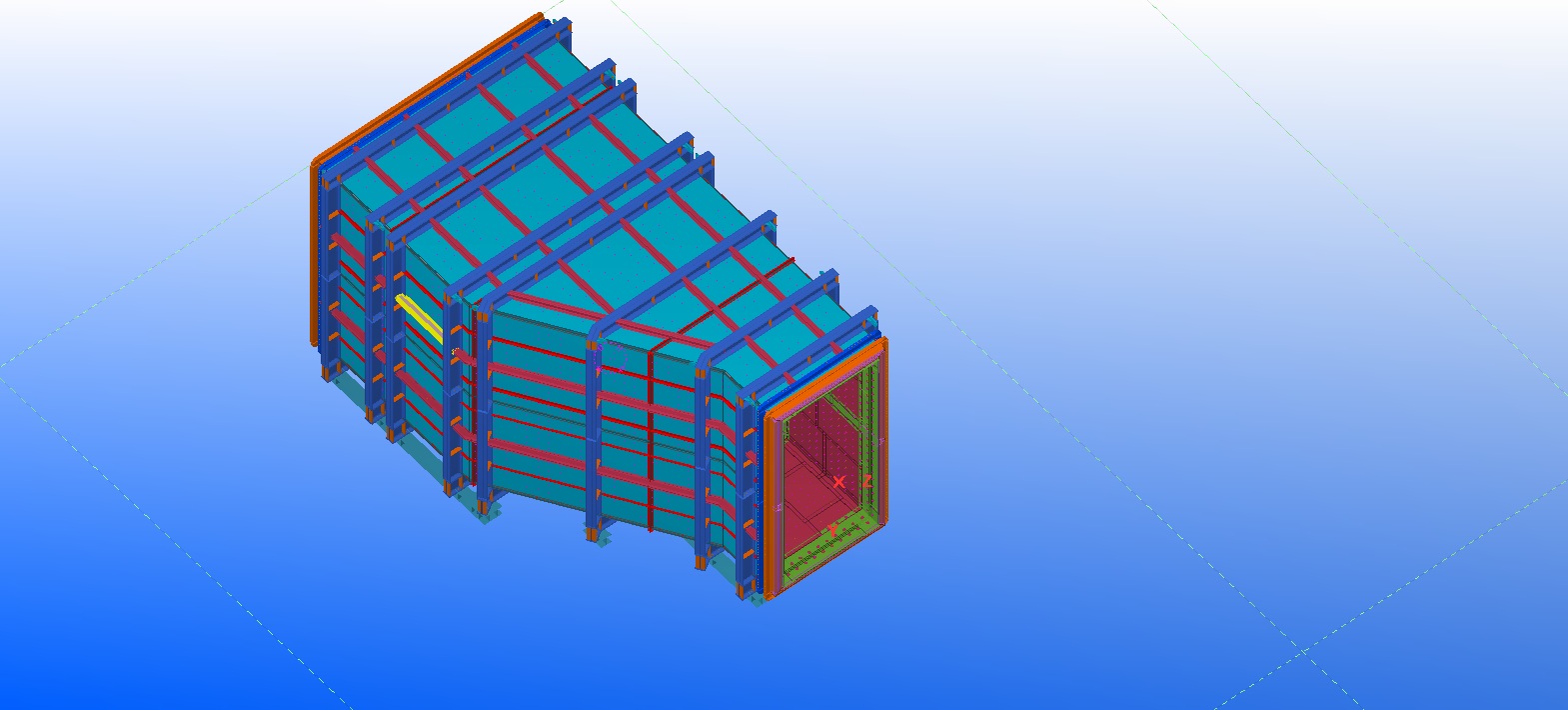

• Execution drawings are detailed plans that guide the construction process. They include:

• Layout Drawing of the Silo Body and Hopper: This shows the overall dimensions and layout of the silo, including the hopper (the part where materials are stored or discharged).

• Assembly Drawings: These provide instructions on how to put together different components of the silo and structure, detailing each part's position and orientation.

• Installation Drawings: These are specific to how the silo will be installed on-site, including information about sequencing, handling, and any temporary supports needed during installation.

4. Single Parts Detailing:

• Each individual component of the silo and its supporting structure may require separate drawings that detail their specifications, such as dimensions, materials, and fabrication details.

• This level of detail ensures that manufacturers can produce each part accurately and that construction teams understand how to assemble them correctly.

Overall, this process is critical for ensuring that the silo is designed for functionality, safety, and efficiency. Proper modeling and documentation help prevent issues during construction and ensure that the final structure meets design specifications.

The subject of this site is the introduction of the teklastructure software and the production of shop maps for use in the workshop. The site also contains information on metal structures, fixed mechanical equipment and relevant standards.

The subject of this site is the introduction of the teklastructure software and the production of shop maps for use in the workshop. The site also contains information on metal structures, fixed mechanical equipment and relevant standards.